Optical Inspection Data Sheet

Main Technical Features

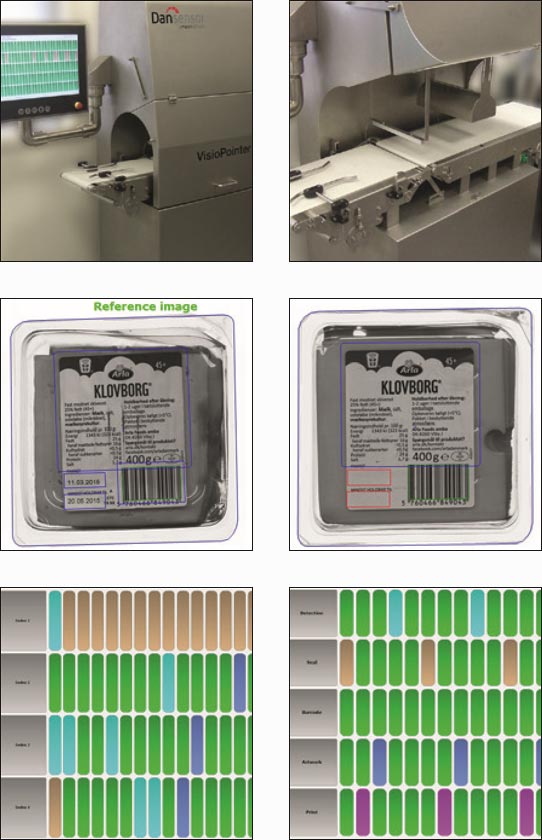

Typical installation

- System installed in the packaging line after the packaging machine and the labeling machine

- The packages pass through the system on a conveyor belt

- Two cameras, one located on the bottom, the other on the top capture the images

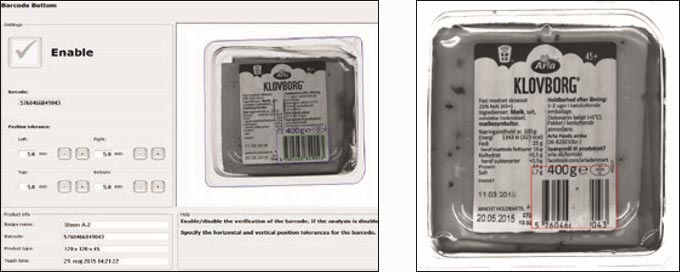

- Each series of images is compared to a defect-free sample image

- It ejects packs that do not respect tolerances

- Production data is stored to analyze the progress of errors and to document the inspection of the product

- It helps identify the causes of errors and actively increases production yield

Inspection of the seal

- VisioPointer detects any visible contamination in the seal, also detects other defects such as welding errors and bends are detected, if they are visible to the human eye

- The sensitivity level is determined by the user and can be assigned with different levels for different types of products

- The percentage of non-compliant seals is specified by the user

- The inspection of the seal is performed constantly and uniformly with greater reliability and continuity than to a visual inspection performed by operators

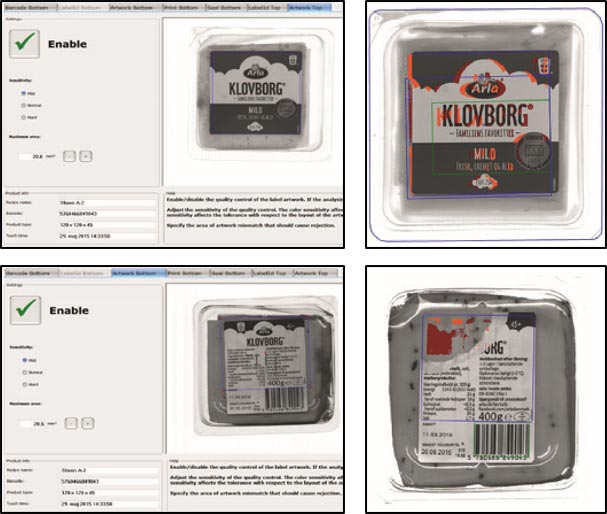

Production optimization module

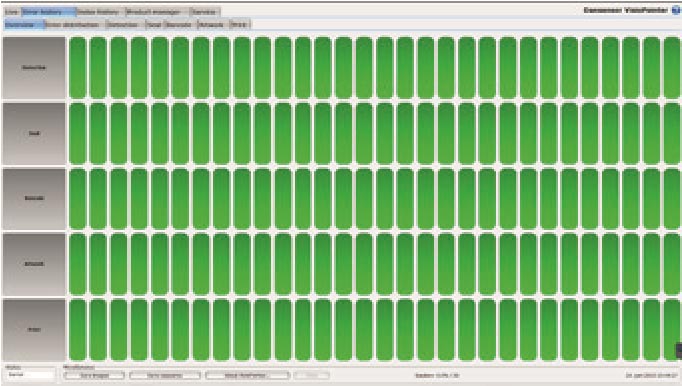

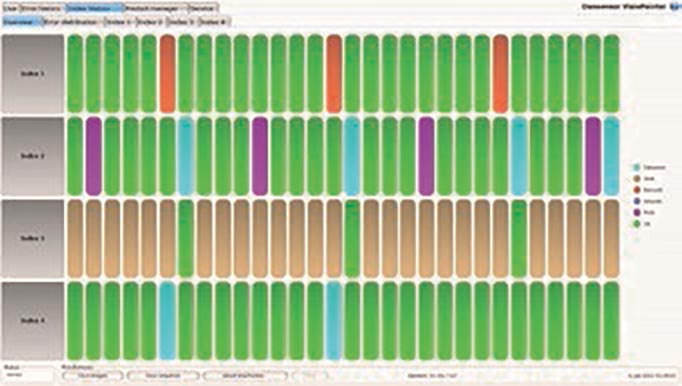

Ogni Colonna Rappresenta una confezione

- The VisioPointer Production Optimization Module ensures that the production line actually makes better products than a line without the VisioPointer System

- The return on investment in a VisioPointer system is very short, while the quality of the products has significantly improved

Ogni barra nella colonna rappresenta il risultato di una specifica ispezione effettuata

- The production optimization system provides

- Instant overview of ongoing production

- With a simple glance, the operator can monitor the status of each quality variable relating to the production line

- Specific and detailed information for a quick return to correct production

- Specific instructions can be linked to each error, to make operator intervention quick and effective

- Statistical data for the maintenance of production lines

Il numero di errori di sigillatura è alto

- The production optimization module associates each error with a specific production line tool

- If an instrument continuously generates products with defects, it will be immediately visible on the POM

- The images relating to each error are stored based on the tool that generates them to give the operator the information necessary to apply rapid corrective actions

Gli errori di sigillatura sono relativi all’index 3

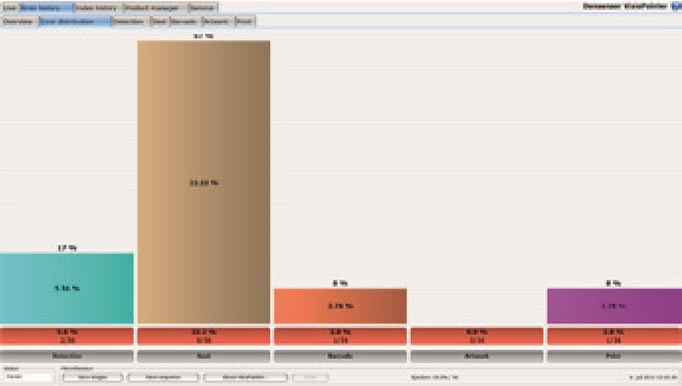

- The error distribution is displayed by error types and by production tools

- If an instrument continuously generates products with defects, it will be immediately visible on the POM

- This provides the maintenance manager with an effective tool to start prevention measures in the correct time